If your parts don’t meet specifications, your customer feels the impact, not your supplier. That’s why it’s essential to know how injection molding services work.

In this process, machines inject melted thermoplastic into a mold to shape plastic components under pressure. You’ll find it behind everyday products, medical devices, furniture parts, packaging, and industrial equipment.

Still, the results depend on more than just the machine. Weak design input, vague tolerances, or poor tooling management can delay production, increase costs, and compromise your reputation.

What Injection Molding Services Encompass

Getting plastic parts molded correctly, on time, to specification, and at scale, is another challenge. That’s where full-service injection molding services come in.

1. Design & Engineering Support

Engineers use Design for Manufacturability (DFM) to adjust wall thickness, gating, draft angles, and other critical details. The goal is simple: prevent flow issues, reduce material waste, and shorten cycle times. Without it, your part may look good on screen, but fail in production.

Material selection also happens here. The right thermoplastic depends on heat resistance, strength, chemical exposure, or compliance needs (like FDA-grade plastics for medical or food contact).

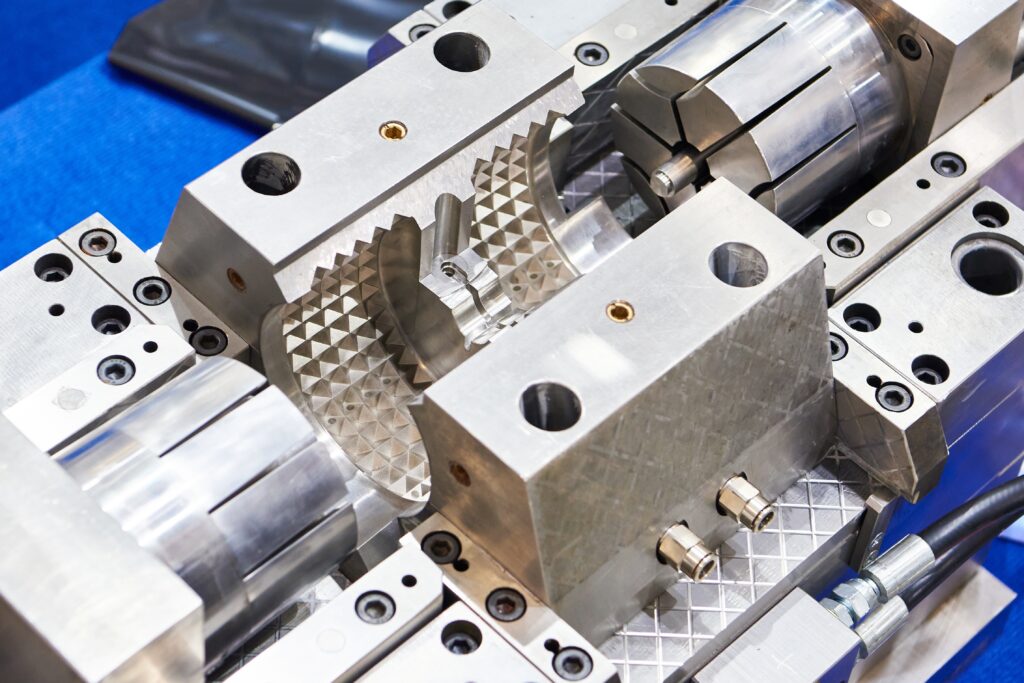

2. Tooling

Mold design and build is about holding tight tolerances under high pressure, for thousands (or millions) of cycles.

Injection molding manufacturing starts with tooling made from steel or aluminum. Your mold might have one cavity or ten, depending on volume and part complexity. Either way, it needs to be precise, durable, and maintained.

Tooling carries high initial costs. Some partners offset it through long-term agreements.

3. Production Molding

This stage involves injecting molten plastic into a mold under high pressure, followed by cooling, ejection, and repeatable cycling. But focusing only on the basics overlooks critical factors that affect production quality and efficiency.

Machine tonnage, part geometry, cycle time, shot size, and equipment capability all play a role in ensuring consistent, high-quality output.

Whether you’re running high volumes or short batches, production molding only delivers consistent results if the setup matches the job.

4. Overmolding and Inserts

Need to combine soft-touch materials with rigid components, or embed electronics or metal inserts?

Overmolding and insert molding integrate multiple materials or elements into a single, functional part. These techniques demand tight alignment and control, while raising complexity.

5. Finishing, Packaging & Fulfillment

The molding process continues beyond part ejection from the press. It continues through:

- Trimming, deflashing, and inspection

- Labeling

- Custom packaging

- Shipping

If you’re stuck coordinating between suppliers, your lead times will suffer.

What to Look For in Injection Molding Services

- Design Support – Applies Design for Manufacturability (DFM) that align with the injection molding process

- Tooling Expertise – Builds precise molds for consistent plastic injection molding

- Material Selection – Identifies thermoplastics suited o your product’s performance

- Volume Flexibility – Supports both high- and low-volume runs while maintaining quality injection molded parts

- Lead Time Management – Delivers reliable schedules

Who are Injection Molding Services For and Not For

Who It’s For:

- Companies needing high-volume production

- Projects requiring complex shapes and precise detailing

- Businesses looking to minimize material waste

- Manufacturers that want to benefit from automated processes

- Those aiming for cost-effective processes

Who It’s Not For:

- Prototypes with high mold costs

- Products with frequent design changes

- Parts with extremely delicate features

Request a Consultation to discuss your project and get expert insights on tooling, design, and production.